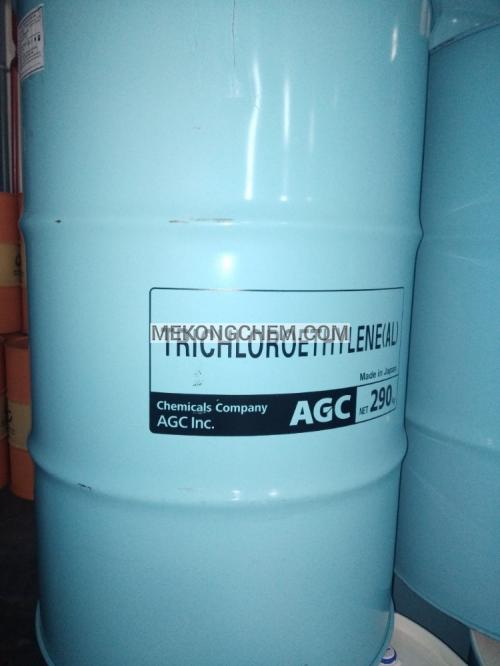

TCE -TRICHLOROETHYLENE - C2HCl3

| FORMULA | : | C2HCl3 |

| ORIGIN | : | Japan |

| PACKING | : | 290kg/drum |

| APPLICATION | : | The greatest use of TCE has been as a degreaser for metal parts |

Short description

Product Name: TCE -TRICHLOROETHYLENE - C2HCl3, C2HCl3, TCE, Trichlor, Trike, Tricky, Trima and Trilene Formula: C2HCl3 Made in Japan Package: 290 kg/steel drum Nature: - Molecular weight: 131.39 g / mol - Appearance: Colorless liquid - Smell: Light sweet - Density: 1.46 g / cm3 - Freezing temperature: -73oC - Boiling temperature: 87.2oC - Water solubility: 1.28 g / L - Steam pressure: 14 kPa - Viscosity: 0.53 cP (25oC) Uses: Trichloroethylene is an effective solvent for a variety of organic materials. Other uses in the food industry included coffee decaffeination and the preparation of flavoring extracts from hops and spices. It has also been used for removing residual water in the production of 100% ethanol. It has also been used as a dry cleaning solvent. The greatest use of TCE has been as a degreaser for metal parts.The chemical compound trichloroethylene is a halocarbon commonly used as an industrial solvent. It is a clear non-flammable liquid with a sweet smell. It should not be confused with the similar 1,1,1-trichloroethane, which is commonly known as chlorothene. The IUPAC name is trichloroethene.

Product Name: TCE -TRICHLOROETHYLENE - C2HCl3, C2HCl3, TCE, Trichlor, Trike, Tricky, Trima and Trilene

Formula: C2HCl3

Made in Japan

Package: 290 kg/steel drum

Nature:

- Molecular weight: 131.39 g / mol

- Appearance: Colorless liquid

- Smell: Light sweet

- Density: 1.46 g / cm3

- Freezing temperature: -73oC

- Boiling temperature: 87.2oC

- Water solubility: 1.28 g / L

- Steam pressure: 14 kPa

- Viscosity: 0.53 cP (25oC)

Production:

Prior to the early 1970s, most trichloroethylene was produced in a two-step process from acetylene. First, acetylene was treated with chlorine using a ferric chloride catalyst at 90 °C to produce 1,1,2,2-tetrachloroethane according to the chemical equation

- HC≡CH + 2 Cl2 → Cl2CHCHCl2

The 1,1,2,2-tetrachloroethane is then dehydrochlorinated to give trichloroethylene. This can either be accomplished with an aqueous solution of calcium hydroxide

or in the vapor phase by heating it to 300-500 °C on a barium chloride or calcium chloride catalyst

- Cl2CHCHCl2 → ClCH=CCl2 + HCl

Today, however, most trichloroethylene is produced from ethylene. First, ethylene is chlorinated over a ferric chloride catalyst to produce 1,2-dichloroethane.

- CH2=CH2 + Cl2 → ClCH2CH2Cl

When heated to around 400 °C with additional chlorine, 1,2-dichloroethane is converted to trichloroethylene

- ClCH2CH2Cl + 2 Cl2 → ClCH=CCl2 + 3 HCl

This reaction can be catalyzed by a variety of substances. The most commonly used catalyst is a mixture of potassium chloride and aluminum chloride. However, various forms of porous carbon can also be used. This reaction produces tetrachloroethylene as a byproduct, and depending on the amount of chlorine fed to the reaction, tetrachloroethylene can even be the major product. Typically, trichloroethylene and tetrachloroethylene are collected together and then separated by distillation.

Uses:

Trichloroethylene is an effective solvent for a variety of organic materials.

Other uses in the food industry included coffee decaffeination and the preparation of flavoring extracts from hops and spices. It has also been used for removing residual water in the production of 100% ethanol.

It has also been used as a dry cleaning solvent.

The greatest use of TCE has been as a degreaser for metal parts.